Lott Brothers Construction was contracted by Ford to renovate an existing building on their research center grounds in Austin, Texas. Lott Brothers Construction is an existing Nation Ramps client, so we looked forward to working on another project with them. Ford required vehicle access to the building at multiple points. The architectural drawings included three ramps to go from grade to the garage level. The design included two vehicle entrances and a single exit. With 12’ wide doorways, they wanted to maximize the ramp widths to handle any possible type of vehicle traffic. Together with Lott Brothers and Ford, Nation Ramps designed three units that met all of their demands to win the contract. Once the contract was awarded the ramp needed to be designed, manufactured, delivered and installed to meet with their strict construction timeline.

The solution was three custom, two-piece ground to dock ramps to be assembled on site. Having worked with many multinational and construction companies, Nation Ramps understood the level of communication and planning required.

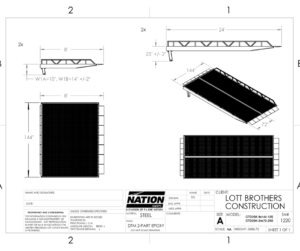

Prior to beginning the manufacturing process, our engineering team produced conceptual design and drawings for discussion and approval. Once Ford management was satisfied with the designs and signed off on the drawings, the ramps were engineered, manufactured, delivered and installed to the project site in Austin, Texas on the requested date.

Our Solution:

GTD25K-12×144-14S x 2 units

2 Section Ramp

Ramp Length 12 Feet

Ramp Width 144 Inches

Ramp Usable Width 139 Inches

Ramp Capacity 25,000LBS (GVW)

Ramp Height – Adjustable 12″ to 16″

Operating Angle Range 7° to 9° (+/- 0.5°)

12” Safety Rub Rails

GTD25K-24×144-25S x 1 unit

2 Section Ramp

Ramp Length 24 Feet

Ramp Width 144 Inches

Ramp Usable Width 139 Inches

Ramp Capacity 25,000LBS (GVW)

Ramp Height – Adjustable 23″ to 27″

Operating Angle Range 7° to 9° (+/- 0.5°)

12” Safety Rub Rails

For Ford, the decision was to manufacture three, two-piece ramps, engineered with a custom heel to allow for maximum adjustability and support. Parameters were: 25,000 lbs. weight capacity, 12’ wide ramps and minimal length to support ground clearance for all vehicles, including the Ford GT. Along with the highly specific design specs, the units needed to have esthetic appeal to compliment the rest of the renovation. Able to handle the wear and tear of continual traffic, offering years of service, while still looking like the day they were installed.

Our Nation Ramps team, including our talented engineering and production staff, worked closely together with Lott Brothers to ensure the final install met the architectural design and vision for the Ford Research Center. Designing for functionality and with high quality North American steel; ensuring that their Research Center operated as efficiently as possible. Chosen by Lott Brothers Construction on multiple projects because Nation Ramps is capable of meeting their custom requirements, delivery deadlines and budget.

Nation Ramps has earned a solid reputation from working with clients like Lott Brothers Construction and Ford throughout the United States and Canada. Delivering quality engineered ground to dock ramps, portable loading docks, equipment loading ramps, stand alone platforms and custom solutions that meet our clients’ demands to improve efficiency; saving time and money.

Questions or interested in learning more? Contact our Ramp Team today!!

RENT | BUY | LEASE – NORTH AMERICAN WIDE

NATION RAMPS FULLY ENGINEERED PORTABLE LOADING DOCK RAMP BENEFITS:

Our Nation Ramps Equipment Loading Dock Ramps are designed with the user in mind. Our clients have the freedom to select one of five product models, (Ground to Dock | Equipment Loading | Portable Loading Dock| Mobile Yard Ramp| Standalone Platform) or customized ramps based on their unique project needs. Our clients benefit from the piece of mind that comes with selecting a ramp that will best help them to mitigate the challenges that often arise on site, saving time and money on all projects.

Choosing a Nation Ramps Portable Ramp provides our clients with multiple and ongoing opportunities to save time and money including:

– An in house loading dock on hand to load / unload freight as needed

– Eliminates having to over handle freight with more than one piece of equipment (including a hand pallet and a forklift)

– Lower labour costs for not having to double handle freight

– The highest level of safety standards available – invaluable peace of mind for clients and their teams

Used Portable Loading Ramp | Forklift Loading Ramps | Heavy Duty Loading Ramps | Mobile Yard Ramp USA | Equipment Loading Ramp USA | Truck Loading Ramp | Yard Loading Ramp

To view more Nation Ramps case studies, click here